Optimizing electric motors is very important in organizations and industries. Considering that electric motors consume more than half of the energy produced in the United States and account for more than 70% of the total energy consumption in many industries, the optimization of energy consumption in electric motors from marine engineering companies in UAE including Al Ghaima is of great importance. Finding faults in engines can be likened to the diagnosis of a patient’s disease by a doctor, so if the doctor does not correctly diagnose the problem, he cannot do anything important to improve the patient, and all the prescriptions he writes will probably not have an effect on his recovery.

In the same way, if the main fault of the electric motors is not known; either the electric motors cannot be repaired, or if another problem has arisen from the original problem and we fix the second problem, there is no guarantee that another problem will occur again and the electric motors will be defective again. If a motor shaft is skewed, the bearings or bushes will get damaged. Just replacing the bearings or bushes without fixing the main issue, the motor shaft misalignment, will result in the bearings or bushes getting damaged again after some time. For instance, consider a motor drawing excessive current that causes winding wire burnout. If only the wire is replaced without addressing the root cause, the motor will burn out again after a while. Although acquiring skills in troubleshooting is mostly the result of practical work and not by reading books and pamphlets, knowing some general and general points in this regard will be very useful for those who just want to start this work.

Optimization of Ventilation and Lubrication

Improving the ventilation and lubrication of engines is one of the main methods that can help their efficiency and performance.

Using a Drive or Engine Speed Controller

Using the drive or speed controller of motors can reduce energy consumption and increase their efficiency.

Regular Maintenance

Regular planning for the maintenance of electric motors is of particular importance and can extend their life.

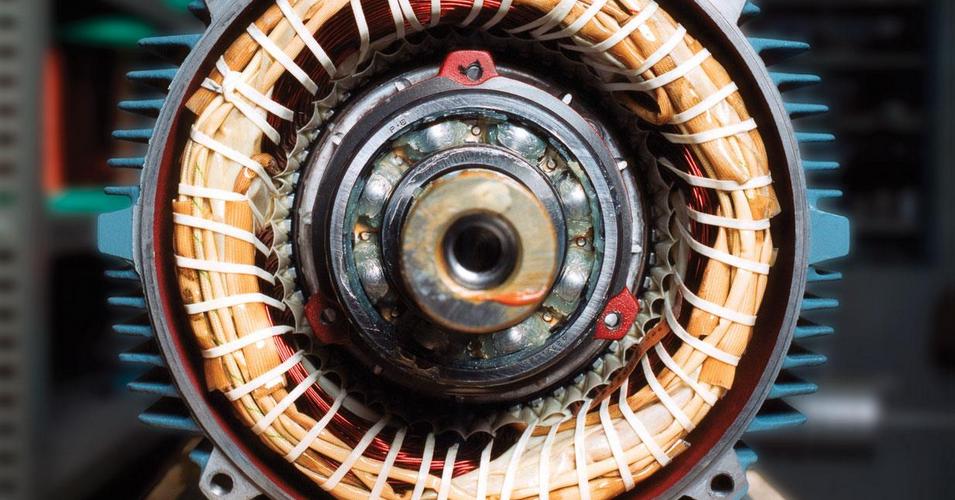

Changing the Number of Stator Poles

By changing the number of stator poles, it is possible to achieve better performance and reduce energy loss in electric motors.

Using Engines with Optimal Performance

Using motors with optimal performance and suitable for specific applications can help improve the performance of electric motors.

Summary

By implementing these steps, and receiving pump repair services optimization measures, the performance of electric motors can be improved and their efficiency can be increased so that they can provide the best performance in performing various tasks.

“The only impossible journey is the one you never begin.” –Tony Robbins